3000PSI Pressure, hydraulic cylinder welded double acting applications

100% hydraulic-pressure tested

Heavy-duty welded construction

ROD, high-tensile steel, hard chrome plated, induction-hardened

Honed steel tube and precision-finished

Ductile iron material for Piston and Gland

All seals are manufactured to US specification

SAE ports available

| Part Number | Rod Dia. | Bore x Stroke | Dimensions | Port Size | Pin Size | Weight (lbs) | |

| Retracted | Extended | ||||||

| TACL30-1504 | 1" | 1.5"x4" | 14-1/4" | 18-1/4" | SAE#6 | 3/4" | 10 |

| TACL30-1506 | 1.5"x6" | 16-1/4" | 22-1/4" | 11 | |||

| TACL30-1508 | 1.5"x8" | 18-1/4" | 26-1/4" | 12 | |||

| TACL30-1508-ASAE | 1.5"x8" | 20-1/4" | 28-1/4" | 13 | |||

| TACL30-1510 | 1.5"x10" | 20-1/4" | 30-1/4" | 13 | |||

| TACL30-1512 | 1.5"x12" | 22-1/4" | 34-1/4" | 15 | |||

| TACL30-1514 | 1.5"x14" | 24-1/4" | 38-1/4" | 16 | |||

| TACL30-1516 | 1.5"x16" | 26-1/4" | 42-1/4" | 17 | |||

| TACL30-1518 | 1.5"x18" | 28-1/4" | 46-1/4" | 18 | |||

| TACL30-1520 | 1.5"x20" | 30-1/4" | 50-1/4" | 20 | |||

| TACL30-1524 | 1.5"x24" | 34-1/4" | 58-1/4" | 22 | |||

| TACL30-1528 | 1.5"x28" | 38-1/4" | 66-1/4" | 25 | |||

| TACL30-1530 | 1.5"x30" | 40-1/4" | 70-1/4" | 26 | |||

| TACL30-1532 | 1.5"x32" | 42-1/4" | 74-1/4" | 27 | |||

| TACL30-1534 | 1.5"x34" | 44-1/4" | 78-1/4" | 28 | |||

| TACL30-1536 | 1.5"x36" | 46-1/4" | 82-1/4" | 29 | |||

| TACL30-2004 | 1-1/8" | 2"x4" | 14-1/4" | 18-1/4" | SAE#8 | 1" | 16 |

| TACL30-2006 | 2"x6" | 16-1/4" | 22-1/4" | 17 | |||

| TACL30-2008 | 2"x8" | 18-1/4" | 26-1/4" | 19 | |||

| TACL30-2008-ASAE | 2"x8" | 20-1/4" | 28-1/4" | 20 | |||

| TACL30-2010 | 2"x10" | 20-1/4" | 30-1/4" | 20 | |||

| TACL30-2012 | 2"x12" | 22-1/4" | 34-1/4" | 22 | |||

| TACL30-2014 | 2"x14" | 24-1/4" | 38-1/4" | 24 | |||

| TACL30-2016 | 2"x16" | 26-1/4" | 42-1/4" | 25 | |||

| TACL30-2018 | 2"x18" | 28-1/4" | 46-1/4" | 27 | |||

| TACL30-2020 | 2"x20" | 30-1/4" | 50-1/4" | 28 | |||

| TACL30-2024 | 2"x24" | 34-1/4" | 58-1/4" | 31 | |||

| TACL30-2028 | 2"x28" | 38-1/4" | 66-1/4" | 35 | |||

| TACL30-2030 | 2"x30" | 40-1/4" | 70-1/4" | 36 | |||

| TACL30-2032 | 2"x32" | 42-1/4" | 74-1/4" | 38 | |||

| TACL30-2034 | 2"x34" | 44-1/4" | 78-1/4" | 39 | |||

| TACL30-2036 | 2"x36" | 46-1/4" | 82-1/4" | 41 | |||

| TACL30-2504 | 1-1/4" | 2.5"x4" | 14-1/4" | 18-1/4" | SAE#8 | 1" | 19 |

| TACL30-2506 | 2.5"x6" | 16-1/4" | 22-1/4" | 21 | |||

| TACL30-2508 | 2.5"x8" | 18-1/4" | 26-1/4" | 23 | |||

| TACL30-2508-ASAE | 2.5"x8" | 20-1/4" | 28-1/4" | 23 | |||

| TACL30-2510 | 2.5"x10" | 20-1/4" | 30-1/4" | 24 | |||

| TACL30-2512 | 2.5"x12" | 22-1/4" | 34-1/4" | 26 | |||

| TACL30-2514 | 2.5"x14" | 24-1/4" | 38-1/4" | 28 | |||

| TACL30-2516 | 2.5"x16" | 26-1/4" | 42-1/4" | 30 | |||

| TACL30-2518 | 2.5"x18" | 28-1/4" | 46-1/4" | 32 | |||

| TACL30-2520 | 2.5"x20" | 30-1/4" | 50-1/4" | 34 | |||

| TACL30-2524 | 2.5"x24" | 34-1/4" | 58-1/4" | 38 | |||

| TACL30-2528 | 2.5"x28" | 38-1/4" | 66-1/4" | 42 | |||

| TACL30-2530 | 2.5"x30" | 40-1/4" | 70-1/4" | 44 | |||

| TACL30-2532 | 2.5"x32" | 42-1/4" | 74-1/4" | 46 | |||

| TACL30-2534 | 2.5"x34" | 44-1/4" | 78-1/4" | 48 | |||

| TACL30-2536 | 2.5"x36" | 46-1/4" | 82-1/4" | 49 | |||

| TACL30-3004 | 1-1/2” | 3"x4" | 14-1/4" | 18-1/4" | SAE#8 | 1" | 24 |

| TACL30-3006 | 3"x6” | 16-1/4" | 22-1/4" | 26 | |||

| TACL30-3008 | 3"x8" | 18-1/4" | 26-1/4" | 29 | |||

| TACL30-3008-ASAE | 3"x8" | 20-1/4" | 28-1/4" | 29 | |||

| TACL30-3010 | 3"x10" | 20-1/4" | 30-1/4" | 31 | |||

| TACL30-3012 | 3"x12" | 22-1/4" | 34-1/4" | 34 | |||

| TACL30-3014 | 3"x14" | 24-1/4" | 38-1/4" | 36 | |||

| TACL30-3016 | 3"x16" | 26-1/4" | 42-1/4" | 39 | |||

| TACL30-3018 | 3"x18" | 28-1/4" | 46-1/4" | 41 | |||

| TACL30-3020 | 3"x20" | 30-1/4" | 50-1/4" | 43 | |||

| TACL30-3024 | 3"x24" | 34-1/4" | 58-1/4" | 48 | |||

| TACL30-3028 | 3"x28" | 38-1/4" | 66-1/4" | 53 | |||

| TACL30-3030 | 3"x30" | 40-1/4" | 70-1/4" | 56 | |||

| TACL30-3032 | 3"x32" | 42-1/4" | 74-1/4" | 58 | |||

| TACL30-3034 | 3"x34" | 44-1/4" | 78-1/4" | 61 | |||

| TACL30-3036 | 3"x36" | 46-1/4" | 82-1/4" | 63 | |||

| TACL30-3504 | 1-3/4" | 3.5"x4" | 14-1/4" | 18-1/4" | SAE#8 | 1" | 29 |

| TACL30-3506 | 3.5"x6" | 16-1/4" | 22-1/4" | 32 | |||

| TACL30-3508 | 3.5"x8" | 18-1/4" | 26-1/4" | 35 | |||

| TACL30-3508-ASAE | 3.5"x8" | 20-1/4" | 28-1/4" | 36 | |||

| TACL30-3510 | 3.5"x10" | 20-1/4" | 30-1/4" | 38 | |||

| TACL30-3512 | 3.5"x12" | 22-1/4" | 34-1/4" | 41 | |||

| TACL30-3514 | 3.5"x14" | 24-1/4" | 38-1/4" | 44 | |||

| TACL30-3516 | 3.5"x16" | 26-1/4" | 42-1/4" | 47 | |||

| TACL30-3518 | 3.5"x18" | 28-1/4" | 46-1/4" | 50 | |||

| TACL30-3520 | 3.5"x20" | 30-1/4" | 50-1/4" | 53 | |||

| TACL30-3524 | 3.5"x24" | 34-1/4" | 58-1/4" | 59 | |||

| TACL30-3528 | 3.5"x28" | 38-1/4" | 66-1/4" | 65 | |||

| TACL30-3530 | 3.5"x30" | 40-1/4" | 70-1/4" | 68 | |||

| TACL30-3532 | 3.5"x32" | 42-1/4" | 74-1/4" | 71 | |||

| TACL30-3534 | 3.5"x34" | 44-1/4" | 78-1/4" | 75 | |||

| TACL30-3536 | 3.5"x36" | 46-1/4" | 82-1/4" | 78 | |||

| TACL30-4004 | 2" | 4"x4" | 14-1/4" | 18-1/4" | SAE#8 | 1" | 35 |

| TACL30-4006 | 4"x6" | 16-1/4" | 22-1/4" | 38 | |||

| TACL30-4008 | 4"x8" | 18-1/4" | 26-1/4" | 42 | |||

| TACL30-4008-ASAE | 4"x8" | 20-1/4" | 28-1/4" | 43 | |||

| TACL30-4010 | 4"x10" | 20-1/4" | 30-1/4" | 46 | |||

| TACL30-4012 | 4"x12" | 22-1/4" | 34-1/4" | 49 | |||

| TACL30-4014 | 4"x14" | 24-1/4" | 38-1/4" | 53 | |||

| TACL30-4016 | 4"x16" | 26-1/4" | 42-1/4" | 57 | |||

| TACL30-4018 | 4"x18" | 28-1/4" | 46-1/4" | 60 | |||

| TACL30-4020 | 4"x20" | 30-1/4" | 50-1/4" | 64 | |||

| TACL30-4024 | 4"x24" | 34-1/4" | 58-1/4" | 71 | |||

| TACL30-4028 | 4"x28" | 38-1/4" | 66-1/4" | 79 | |||

| TACL30-4030 | 4"x30" | 40-1/4" | 70-1/4" | 83 | |||

| TACL30-4032 | 4"x32" | 42-1/4" | 74-1/4" | 86 | |||

| TACL30-4034 | 4"x34" | 44-1/4" | 78-1/4" | 90 | |||

| TACL30-4036 | 4"x36" | 46-1/4" | 82-1/4" | 94 | |||

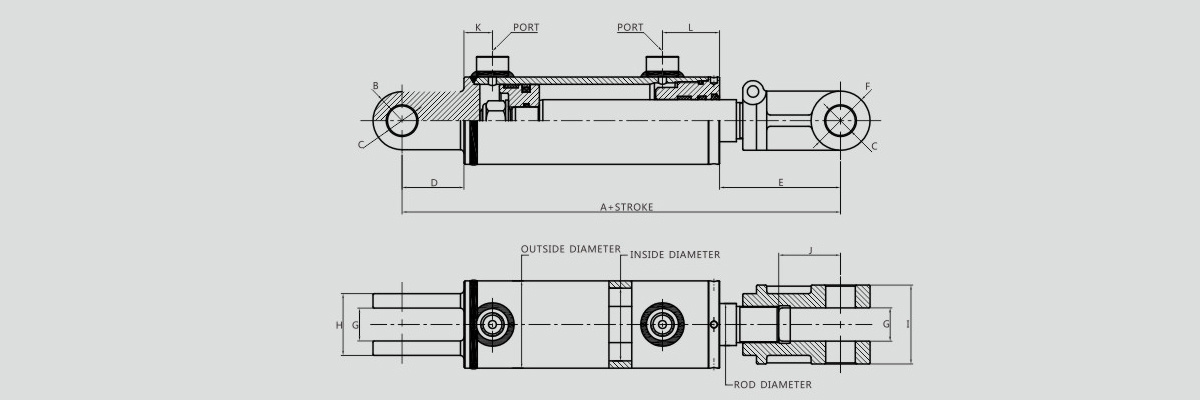

| PART NUMBER | INSIDER DIAMETER | OUTSIDER DIAMETER | *A | B | C | D | *E | F | G | H | 1 | J | K | L | ROD THREAD | ROD DIAMETER | POR |

| TACL15- | 1.50" | 2.00" | 10.25" | 1.50" | 0.76" | 1.62" | 4.50* | 1.87, | 0.87" | 1.75" | 2.00" | 1.62" | 0.93" | 1.87" | 0.875-14 UNF | 1.00" | SAE#6 |

| TACL20- | 2.00" | 2.50" | 10.25" | 2.00" | 1.01" | 2.12" | 3.62" | 2.25" | 1.12" | 2.12" | 2.62" | 2.12" | 0.81" | 2.06" | 1.125-12 UNF | 1.12" | SAE#8 |

| TACL25- | 2.50" | 3.00" | 10.25" | 2.00" | 1.01" | 2.12" | 3.62" | 2.25" | 1.12" | 2.12" | 2.62" | 2.12" | 0.81" | 2.06" | 1.125-12 UNF | 1.25" | SAE#8 |

| TACL30- | 3.00" | 3.50" | 10.25" | 2.00" | 1.01" | 1.87" | 3.62" | 2.25" | 1.12" | 2.62" | 2.62" | 2.12" | 0.87" | 2.18" | 1.250-12 UNF | 1.50" | SAE#8 |

| TACL35- | 3.50" | 4.00" | 10.25" | 2.00" | 1.01" | 1.87" | 3.62" | 2.50" | 1.12" | 2.62" | 2.75" | 2.12" | 0.93" | 2.18" | 1.500-12 UNF | 1.75" | SAE#8 |

| TACL40- | 4.00" | 4.50" | 10.25" | 2.25" | 1.01" | 1.75" | 3.62" | 2.50" | 1.12" | 2.62" | 2.75" | 2.12" | 1.00" | 2.18" | 1.500-12 UNF | 2.00" | SAE#8 |

| *FOR 8.00" STROKE :*A= 12.25" | |||||||||||||||||

| *FOR 8.00" STROKE :*E= 6.50"(1.50" BORE) *E= 5.62"(2.00" TO 4.00" BORE) | |||||||||||||||||

| SEAL TEMPERATURE RANGE: -30°C/+100°C(-22°F/ + 212°F) | |||||||||||||||||

| SEAL MAXIMUM SPEED:3 FT/SEC | |||||||||||||||||

| MAXIMUM RETRACTED WORKING PRESSURE 3000 PSI | |||||||||||||||||

| DIMENSIONS A AND E ARE FOR REFERENCE ONLY AS CLEVIS IS ADJUSTABLE | |||||||||||||||||

If you're considering the ACL Adjustable Welded Clevis Hydraulic Cylinder, you might also be interested in our other high-quality welded hydraulic cylinders for sale.

1. The WBU Cross-Tube Welded Hydraulic Cylinder is designed for robust performance and reliability, making it ideal for demanding applications.

2. The WCL Clevis Welded Hydraulic Cylinder offers exceptional durability and precision, perfect for various industrial needs.

3. The WTH Pin Eye Welded Hydraulic Cylinder provides consistent performance in a wide range of environments.

When it comes to sourcing adjustable welded clevis hydraulic cylinders, Hutchin Hydraulic stands out as a trusted partner known for precision engineering, exceptional durability, and customer-centric solutions. With over 20 years of industry expertise, Hutchin has built a strong reputation for delivering reliable, high-performance cylinders tailored to the needs of demanding industrial applications.

Our ACL series welded clevis hydraulic cylinders are manufactured with a deep commitment to quality, from high-strength steel construction and precision-welded end caps, to the integration of adjustable stroke features that support versatile positioning in complex systems. Each cylinder is rigorously tested for pressure, performance, and sealing integrity, ensuring consistent and safe operation even in the harshest environments.

At Hutchin Hydraulic, we don't just supply adjustable hydraulic cylinder products—we provide customized hydraulic solutions backed by responsive service, fast delivery, and strict adherence to international standards. Whether you need OEM support, specific mounting configurations, or enhanced sealing options, our team is ready to engineer a solution that fits.

A welded double acting hydraulic cylinder is a robust and efficient solution for applications that require force in both directions—extension and retraction. Unlike single acting cylinders, double acting cylinders use hydraulic pressure on both sides of the piston, allowing for precise control of motion and consistent power delivery throughout the stroke.

Welded construction: offers superior strength, leak resistance, and compact design compared to tie-rod cylinders. Ideal for heavy-duty and space-constrained applications.

Double acting operation: provides hydraulic power in both directions, enhancing control and versatility in complex systems.

High-quality seals: designed to withstand high pressure and prevent internal or external leakage.

Chrome-plated rod: ensures corrosion resistance and extended wear life, even in harsh environments.

Clevis, cross tube, or custom mounts: available with multiple end configurations to suit various installation requirements.