In the world of heavy machinery, dump cylinders play a critical role in the operation of dump trailers and trucks. These powerful components are essential for managing the load and unloading processes, ensuring efficiency and safety on the job site. Whether you're a seasoned professional or new to the field, understanding how dump cylinders work can enhance your operational skills and equipment maintenance.

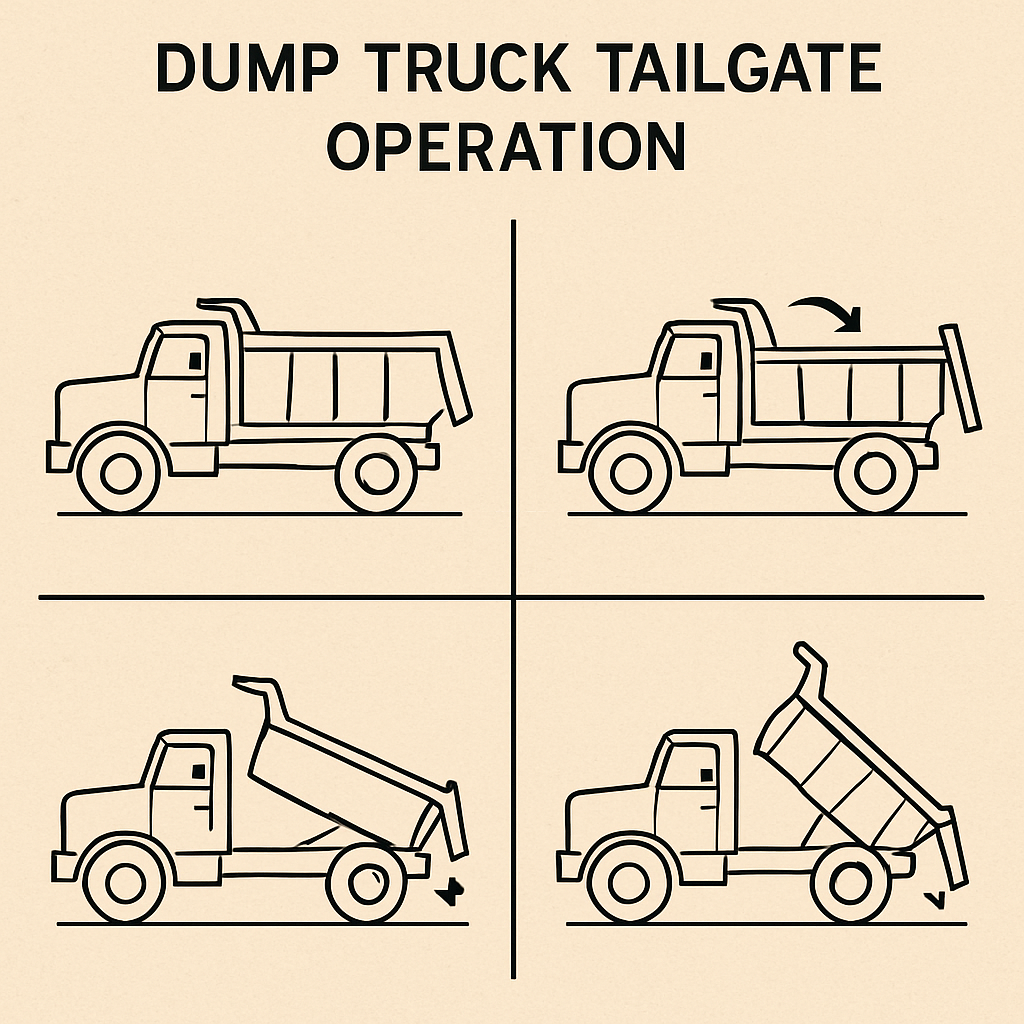

Dump cylinders are hydraulic components that are primarily used in dump trailers and dump trucks. They are responsible for lifting and tilting the truck bed to facilitate the unloading of materials like gravel, sand, or debris. Hydraulic systems are known for their ability to provide powerful, controlled movement, and dump cylinders are no exception.

The functionality of a dump trailer hydraulic cylinder relies on hydraulic pressure. When hydraulic fluid is pumped into the cylinder, it creates pressure that pushes the piston, extending the cylinder and lifting the truck bed. Conversely, when the fluid is released, the pressure decreases, and the piston retracts, lowering the bed back into place.

Cylinder Barrel: This is the outer casing that houses the piston and hydraulic fluid.

Piston: The moving component that extends and retracts within the cylinder.

Hydraulic Fluid: The medium used to transfer force within the cylinder.

Seals: These ensure that the hydraulic fluid remains contained within the cylinder.

There are various types of dump cylinders, each designed for specific applications:

1. Single-Acting Cylinders: These use hydraulic pressure to extend the piston in one direction, with gravity or another force bringing it back.

2. Double-Acting Cylinders: These utilize hydraulic pressure for both extending and retracting the piston, providing more control and precision.

In addition to dump cylinders, dump truck tailgate air cylinder kits are often used to manage the opening and closing of the truck's tailgate. These kits use compressed air to operate, providing a convenient and efficient means of controlling the tailgate remotely.

Regular maintenance of your dump cylinders and related components is crucial for optimal performance. Here are some tips:

Inspect Regularly: Check for leaks, cracks, or any signs of wear and tear.

Keep It Clean: Ensure that the hydraulic system is free from dirt and debris to prevent contamination.

Monitor Fluid Levels: Always maintain the correct hydraulic fluid levels to ensure efficient operation.

Understanding the functionality of dump cylinders and maintaining them properly can significantly improve the efficiency and lifespan of your equipment. By keeping these essential components in good working order, you ensure safety and reliability on every job.

If you have experiences or tips about dump cylinders, feel free to share them in the comments. Your insights could be invaluable to others in the field.